Custom Made Electrical Connectors

- High Current Connectors

- Heat- Resistant Connectors

- Vacuum Connectors

- Special Purpose Connectors

Features of Connectors Using Electrical Contact

- Reduces loss of electricity when high current is applied due to low-contact resistance

- Longer life for repeated insertion and extraction

- Capable of reducing insertion and extraction force and suitable for multi-polarity

- The multipoint contact structure moves independently for tracking when an irregular

- Applicable in high temperature environments

- Resistant to oxide film due to inherent self-cleaning function

- Compact size in the direction of diameter and axis

- Compensates for mating misalignment

- Stabilizes signal voltage

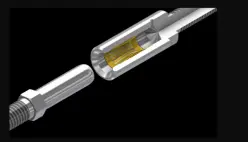

Contact Band and Coil Spring Contact

Two types of electrical contacts—The Contact Band and Coil Spring Contact—are used in Globetech connectors. The contact band is manufactured by pressing a sheet of high-performance spring material. The coil spring contact is manufactured by winding wire materials to create a spring consisting of canted coils and then welding them to form a circular shape.We choose the optimum type for each contact depending on the specifications, application, and cost, and then we design a connector best suited to the needs of the customer.

Features and Type of Contact Band

- Silver plating or gold plating on beryllium copper alloy

- Louver structure suited for energization of high current

- Low cost and mass production using a progressive die

- Made-in-Japan products ensure high quality

- Contacts in different diameters and contact band types are available in the inventory

- Superior capability to remove oxide film thanks to the wiping function of the heat cycle

Features and Type of Coil Spring Contact

- The canted coil spring contact incorporated into our connectors is supplied by Bal Seal Engineering Inc. of the United States, the holder of its manufacturing technology

- Offers a wide range of working deflection and the repelling property is stable

- Compensates for dimensional error and misalignment

- Various materials having superior heat resistance, corrosion resistance, and resistance to the environment, including stainless steels and nickel alloy are offered in addition to beryllium copper alloy

- Applicable to different sizes with a wide range of pin diameters and lengths

- Longer life and lower insertion and extraction force from multipoint contacts and low contact pressure